PRACTICAL AND COMMERCIAL UNITS

المؤلف:

Mark Csele

المؤلف:

Mark Csele

المصدر:

FUNDAMENTALS OF LIGHT SOURCES AND LASERS

المصدر:

FUNDAMENTALS OF LIGHT SOURCES AND LASERS

الجزء والصفحة:

p278

الجزء والصفحة:

p278

24-3-2016

24-3-2016

2119

2119

PRACTICAL AND COMMERCIAL UNITS

Most commercial excimer lasers start in the low $10,000 range and are priced up to $200,000. A major additional cost is that of installation and operation. These costs vary depending on the ultimate use of the laser; a laser designed for industrial processing must often operate at pulse rates of 300 Hz for extended periods of time, generating an average power of over 100 W, whereas a small excimer designed for eye surgery may be required to fire at most once per second. Clearly, there will be huge differences in the way such a variety of lasers will be built. The industrial laser is often designed for high throughput and reliability, with many components (such as optics and the main capacitor) designed to be changed in the field in much less than an hour, while the low firing rate of the surgery laser may well mean that a laser capable of only 1 million shots in its entire lifetime is more than adequate for the application! An excimer of this type does not have to be designed for fast serviceability, but it may be required to generate extremely consistent pulse energies to yield predictable tissue removal.

Installation of most large excimer lasers requires expensive gas-handling apparatus, including gas cabinets and leak detectors. The alternative employed by one manufacturer (Oxford Lasers, which holds a patent on the method) is to generate halogens in the laser itself by heating a fluorinated salt:

K3NiF7 → K3NiF6 + F

This material is uncommon, though, and must be specially prepared. In the laser the salt is heated to over 300oC to release fluorine. Although a fluorine generator does eliminate the need for a gas cabinet as well as a bottle of fluorine, these generators are not cheap either, and it is claimed (by competing manufacturers) that exposure of the generator to water vapor in air essentially ruins the generator, which must then be reprocessed. When dealing with a gas such as fluorine, there is no such thing as a cheap or convenient source; most major excimer manufacturers use bottled supply gases.

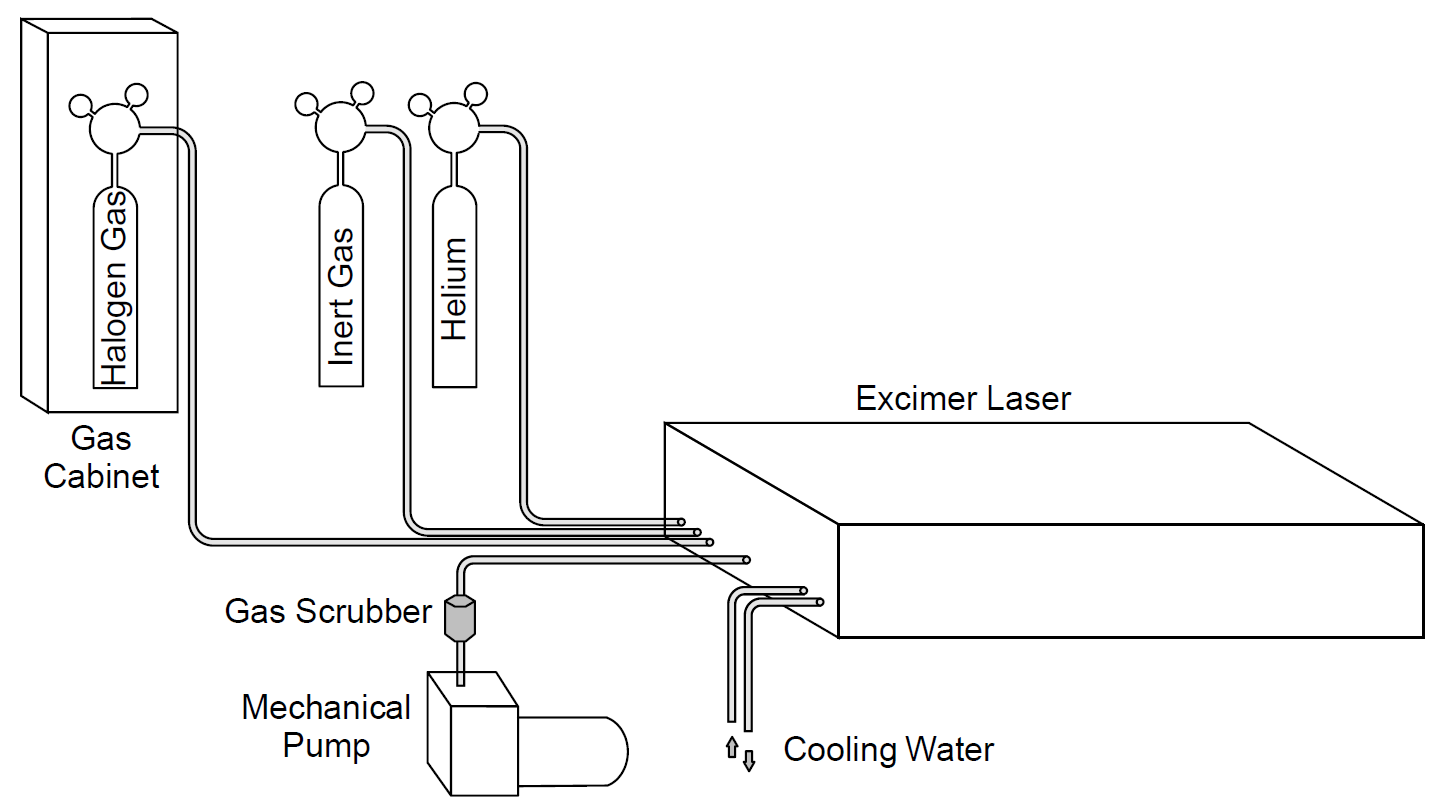

In addition to the halogen gas (the most difficult gas to handle in the system), buffer and inert gases are also required in high-purity form. A typical excimer laser installation is depicted in Figure 1.1. Most excimer lasers can use a variety of gas mixtures with only a change of optics to suit the wavelength emitted (if required many materials transmit over a large enough range that they work with many gases emitting in the UV). For ultimate flexibility (e.g., in a research environment) an excimer laser would be supplied with two halogens (fluorine and hydrogen chloride), three

Figure 1.1.Typical excimer installation.

rare/inert gases (argon, krypton, and xenon) and two buffer gases (helium and neon). Many commercial lasers have large manifolds attached, allowing connection of many gases to the system; the smallest manifolds usually have four ports whereas many research-class lasers feature up to eight. In industry many excimers are dedicated to lasing a single excimer species, so the gas requirements are simplified as shown in Figure 1.1, which depicts a minimal excimer system. The gas scrubber, a cylinder filled with soda lime and a molecular sieve material, is essential for removing active fluorine (or chlorine) from exhaust gas (given its toxicity) before pumping into the atmosphere. Of course, where the excimer is used to lase a carbon dioxide or nitrogen laser line, the gas requirements are much simpler since none of the gases used are toxic or corrosive.

Some excimer systems, used for a fixed purpose such as eye surgery, use a convenient premixed gas supply containing argon and fluorine to simplify the system. One popular manufacturer of lasik surgery systems employs only two gases premixed ArF and a buffer gas simplifying the gas system for the laser. The laser is operated at only 40% of its maximum pulse energy, which is stabilized by adjusting capacitor voltage. When voltage reaches a preset limit, fresh premixed gas is injected into the laser (called a boost) to raise the output power to acceptable limits at minimum capacitor voltage. The laser then operates with this fill, and voltage is raised again to compensate for gas loss. The goal of this methodology, of course, is to produce consistent energy in repetitive pulses so that the surgeon will know precisely how much tissue will be ablated on each pulse.

Aside from gas supply (the biggest concern with this type of laser), most excimers also require a supply of cooling water and three-phase power. Whereas a small excimer with a 40-W output may require 20 A at 110 V, a larger excimer producing 150 W of output requires 30-A, 208-V, three-phase service. Typical efficiency for a commercial KrF laser (the most efficient excimer) is about 1.5%, so a KrF laser with a 100-W optical output would consume almost 7 kW of electrical energy. Operation of most excimer lasers is simplified greatly by computerized controls which mix gases automatically and refill the laser with fresh gas as required. A single gas fill can last millions of shots but must eventually be discarded (first by scrubbing the halogen from the mixture) and then refilled with a fresh fill. To extend the gas-fill lifetime, extra halogen gas can be injected into the mixture during operation, which also serves to increase output power, which decreases as the laser is run and halogen concentration decreases. One manufacturer claims gas-fill lifetimes of 50 million shots using KrF with automatic replenishment. Many large excimer installations also feature a cryogenic gas processor: The same KrF laser boasts 120 million shot gas lifetimes on a single KrF fill using a gas processor. Operating costs of a modern excimer laser, with features designed to extend the gas-fill lifetime, are claimed to be about $15 per hour for a laser operating continually at 150 Hz. With advances made to extend gas-fill lifetime, the largest operating expense is no longer gas supply, but inevitable replacement of electrical components.

Before operating an excimer that has been opened to the atmosphere, left unused for a period of time (ranging from a week to over a month, depending on the man- ufacturer’s recommendations), or when changing gas mixtures from a fluoride to a chloride gas mix (or vice versa), passivation of the laser is required. In passivation a layer of metallic halogen is deposited on internal metal components to prevent further absorption and reaction with halogens in the laser gas mix. In this operation a mixture consisting of a small percentage of the halogen used (fluorine or hydrogen chloride) in a buffer of helium is either left in the (not operating) laser overnight, or the laser is operated for about an hour with a passivation gas mixture. This process is somewhat involved and time consuming, so most excimer users prefer to keep the laser operating with one type of excimer (fluoride or chloride) and not switch between the two.

Aside from gas supply and the occasional passivation, other maintenance required for an excimer laser includes cleaning of optics. Unfortunately, cleaning the internal surface of cavity optics (which must be done at intervals of every 50 to 100 million pulses, which may be as short as two days for a system under continual use) may well force the user to bring the laser vessel to atmosphere, which would require passivation again before use (unless the vessel is constantly purged with a supply of inert gas during the process). Some manufacturers (e.g., GSI Lumonics) have solved this problem by offering gate valves between the tube and the optics so that optical elements may be removed while the laser channel stays pressurized with the excimer gas mix. In such a design passivation is not required when optics are changed since air never enters the laser pressure vessel and the gas fill in the laser is preserved. Finally, electrical components such as the main capacitor and thyratron have finite lives and must be replaced periodically. Although late-model lasers employ optimized discharge paths extending thyratron lifetime to over 1 billion pulses, so reliability of electrical components has improved drastically over earlier designs.

الاكثر قراءة في بعض تطبيقات الليزر

الاكثر قراءة في بعض تطبيقات الليزر

اخر الاخبار

اخر الاخبار

اخبار العتبة العباسية المقدسة